[Home] [Back to Ironwork & Metalwork page] [Iron & Copper Entryway Gate] [Beautiful Fountain, Nurenburg Germany] [Modern Brass & Glass Railing] [Baroque Drive Gate Reproduction]

UPDATED September 16th, 2019.

October 2000.

Built around the winter of 1996. It is always fun to get a fancy piece of ironwork placed outside one of the top 10 most expensive houses in the Des Moines area. And it is an excellent way to attract more of the best business clients.

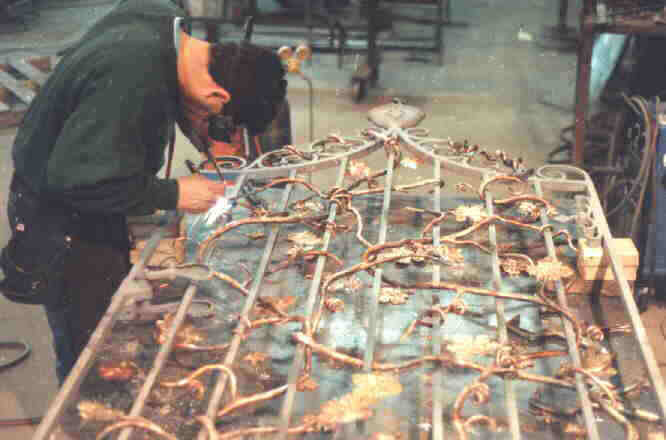

Here we built a plain iron gate which otherwise would have presented a rather boring feature, but through the vertical bars of the gate we wove copper vines and added copper leaves hand hammered in their entirety. A set of lightly carved steel hinge escutcheons and a fancy matching lock plate breaks up the outline of the posts to which the gate is mounted. A pair of hand carved forged handle pulls made in the Viennese style, and a lightly carved lock cover accents the light and cheery appearance.

The lock strike plate and the hinge escutcheons were carved from steel plate. Slitting and hammering the plates created the gothic styling of the plates. Copper sheet was cut in several patterns and styles of leaves. I forged some special 'chisels' which were used to vein the leaves over a block of lead. Simple designs actually. The vines are made of several sizes of copper bars. The 'trunks' of the vines were built up of several layers of copper bar stock and welded with copper MIG. The vines were interwoven through the bars and scrolls of the gate with the aid of a torch to heat and soften them. The squiggles were turned on a special scrolling jig similar to a hand cranked chain mail coil maker used by armourers of old.

The vines are attached only by winding around

around the iron bars and scrollwork. The bottom of the vines were held to the bottom

horizontal frame member with screw which threaded up inside the base of the trunk of the

vine.

The vines are attached only by winding around

around the iron bars and scrollwork. The bottom of the vines were held to the bottom

horizontal frame member with screw which threaded up inside the base of the trunk of the

vine.

The branches and squiggles of the vines were welded together as work progressed using a MIG welder and copper wire. A torch was also used to preheat the copper metal as required before welding.

Photo near right is a detail view of the strike plate for the lock. The incised lines and hammering are clearly visible and it can be seen how this leads the eye along the outline of the plate. At far right is a close detail view of the carved handle pull and lock. The picture was a bit blurry but look closely and the carved lines are visible on the curved and cupped outsides of the handles. Also visible are the incised lines carved in the lock cover. The ends of the handle pulls are forged into a lean scrolled tendrils which curls beneath and terminates beneath the cupped handle.

The copper was

very stiff from the hammering we performed to texture it. A natural gas and oxygen torch

softened the copper bars in strategic points allowing us to weave the the copper through

the bars. The bars were about 6 feet long to start and were folded upon themselves to

allow them to be passed in and around the iron bars and scrolls. The copper was

straightened as work progressed but we left the curves and kinks for effect, everywhere

that we unfolded the bars.

The copper was

very stiff from the hammering we performed to texture it. A natural gas and oxygen torch

softened the copper bars in strategic points allowing us to weave the the copper through

the bars. The bars were about 6 feet long to start and were folded upon themselves to

allow them to be passed in and around the iron bars and scrolls. The copper was

straightened as work progressed but we left the curves and kinks for effect, everywhere

that we unfolded the bars.

Leaves were attached using a special type of solder or brazing alloy which melts at a higher temperature. Copper transmits heat along its length quickly enough that regular electronic or plumbers' solder, would have melted too easily when multiple leaf stems were soldered nearby each other. In that case assembly would have not allowed us to fasten leaves near each other. The higher melting temperature of the alloy allowed closer attachment of the leaves. The alloy was also much stronger than solder.

Latest update October 24th, 2000.

The author can be emailed at address in picture below:

Page created October 2000.